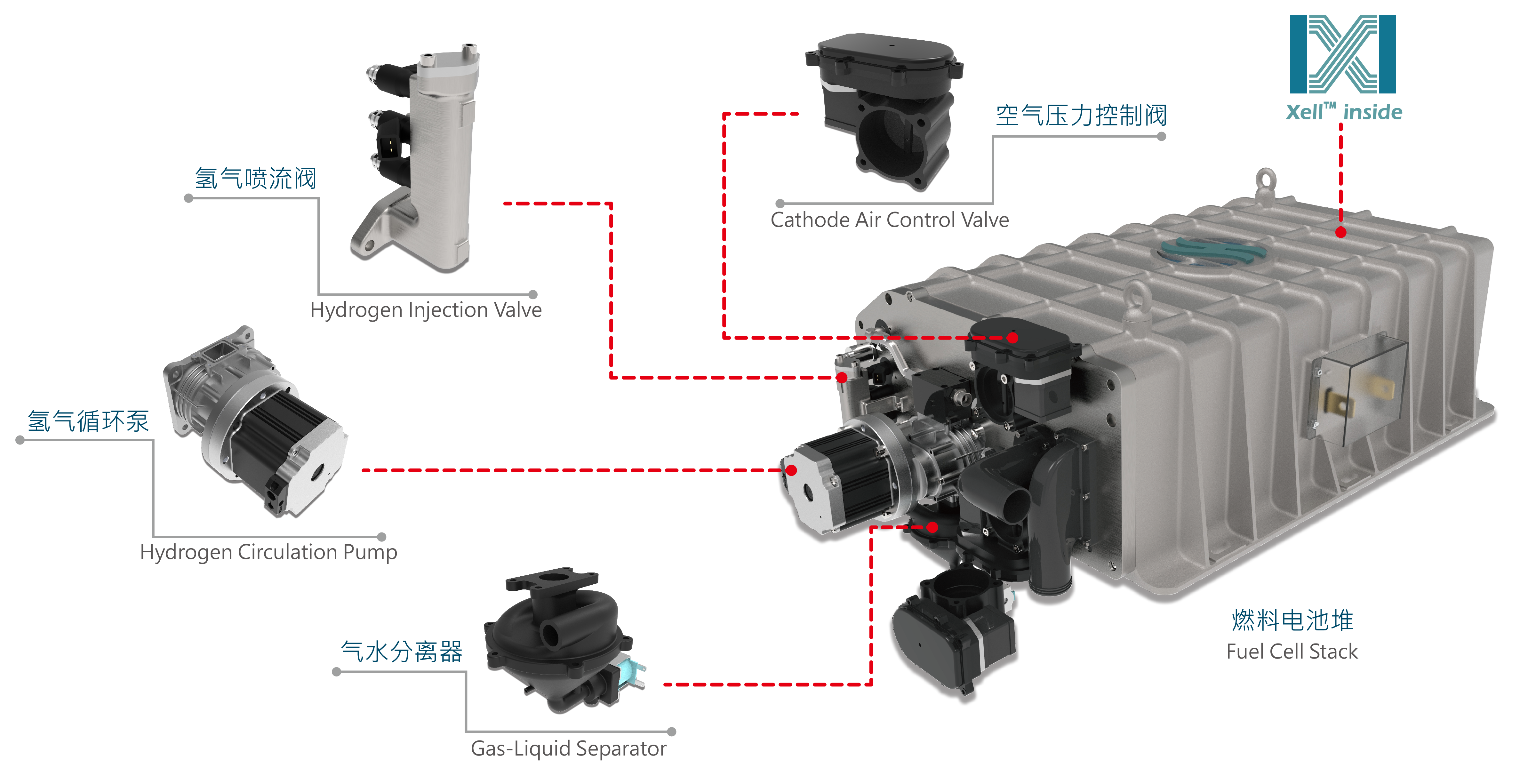

APT has developed a series of exclusive component BOPs for Xell™ stack, including back-pressure valves, flow diverter valves, hydrogen injectors, gas-liquid separators, hydrogen recirculation pumps, etc., to provide customers with a wide range of selection for developing their fuel cell power systems.

Cathode Air Control Valve

- To regulate air pressure supplied to the fuel cell stack.

- Butterfly valve ensures low pressure loss and excellent flow control.

- Special mechanism design maintains operability and corrosion. resistance at temperatures below freezing point.

- The impermeable coating prevents the water that penetrates into the space between the valve and the hole from freezing.

Hydrogen Injector

- Sophisticated hydrogen supply technology simultaneously adjusts the anode hydrogen inlet pressure and flow rate.

- Three ejectors in tandem improve the stability and reliability of hydrogen supply.

- Modular design with small size and lightweight.

- PWM control responds to the change in operating conditions from idling to high duty.

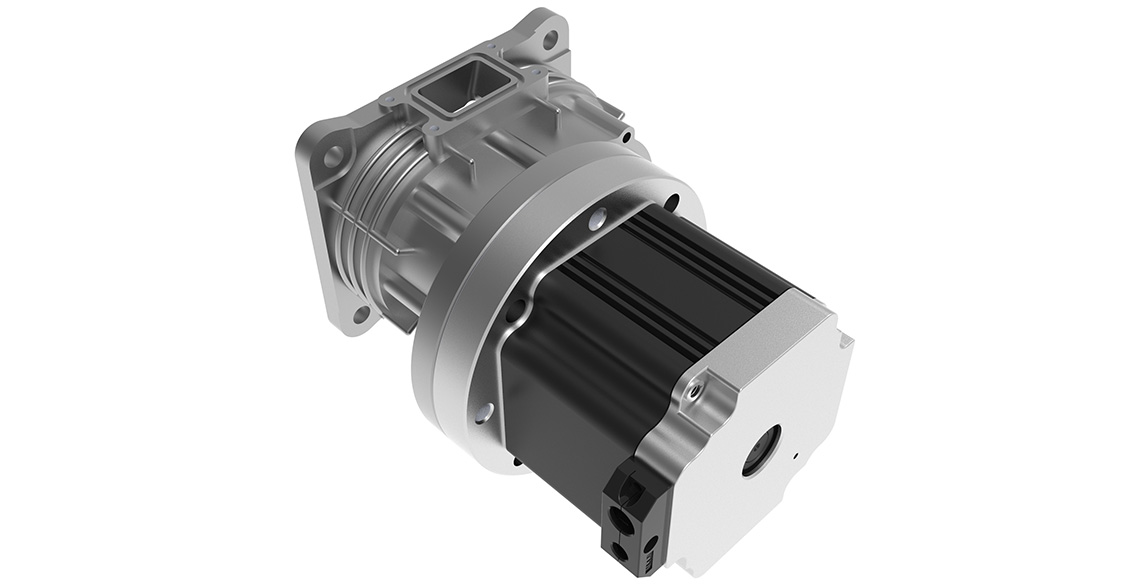

Hydrogen Circulation Pump

- Special double-lip seal design provides a gastight environment for hydrogen circulation.

- Special coating on the blade surface provides high-performance lubrication conditions.

- Integrated design of the hydrogen circulation pump and the stack endplate improves the heat dissipation performance of the motor and achieves a more compact system size.

Gas-Liquid Separator

- Patented spiral-shaped cyclone structure separates water droplets through centrifugal force.

- Patented hydrophilic filter removes out macromolecular water vapor.

- Secondary exhaust flow path design reduces the possibility of freezing and blocking in the channel connection.

- Combining the hydrogen circulation pump makes the fuel cell system more compact.