Fuel Cell System and Subsystem

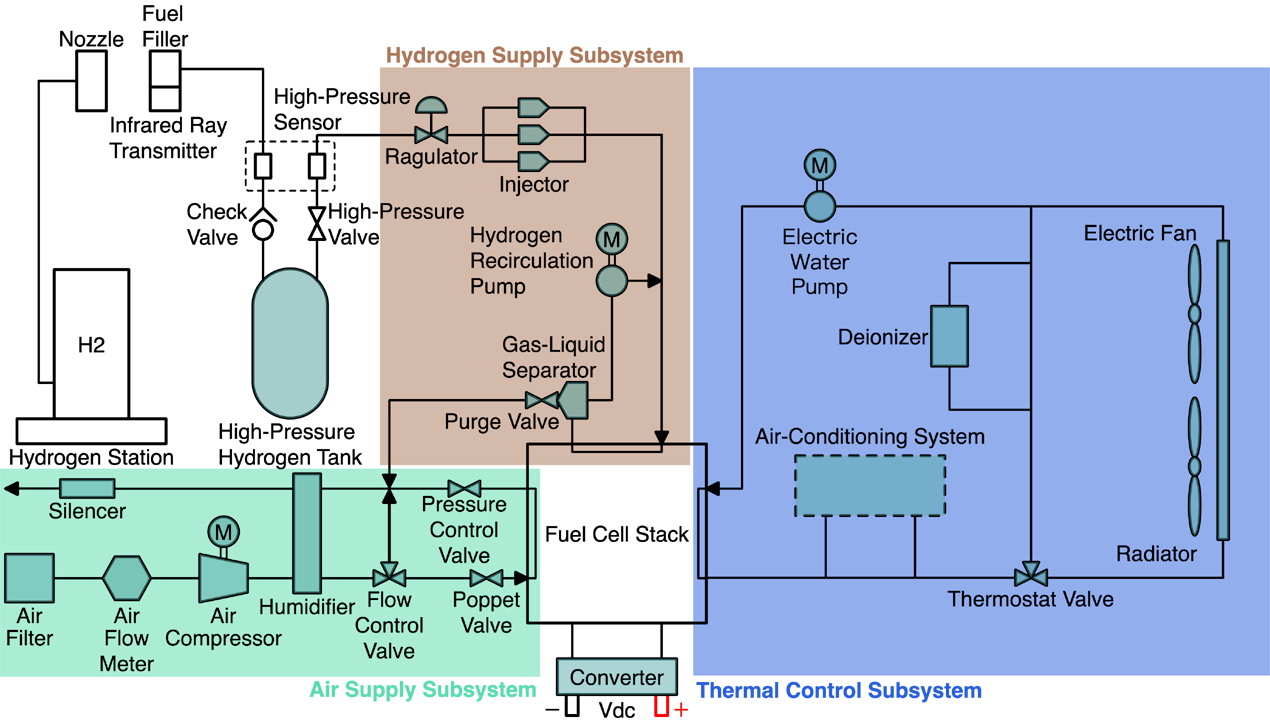

In addition to a fuel cell stack, a fuel cell system must include some BOPs, such as an air booster, a refrigerant pump with a radiator, a hydrogen circulation pump, a fuel cell controller, etc.Before system integration, APT divides the fuel cell system into several subsystems for testing and analysis, including the hydrogen supply subsystem (orange block), air supply subsystem (green block), and thermal control subsystem (blue block). APT uses the test results on the subsystem test platform, in a combination of the simulation results from system dynamic analysis, to confirm each BOP characteristics, as a reference for BOP selection and design of control strategies, which can greatly shorten the system development time.

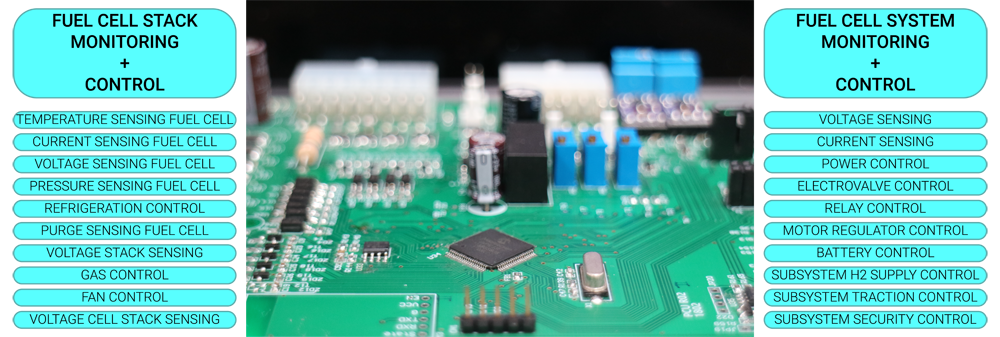

Fuel Cell Controller

The fuel cell controller is the command center of the fuel cell system. It has three main functions, i.e., to start the fuel cell system, to ensure the stable operation of the system, and to shut down the fuel cell system. The fuel cell controller executes the control strategies to direct all sub-systems and monitors the operation status in real time by using various sensors (e.g., temperature, pressure, flow rate, humidity, etc) to ensure the stability and safety of the system operation. APT has developed a dedicated fuel cell controller, which can accurately control the fluid, maintain the stable operation of the fuel cell system, and improve the efficiency and life of the fuel cell system. It has the following characteristics.

- High-speed operating capability: It uses 32-bit DSP high-speed processor with built-in high-resolution ADC and quick PWM output.

- Precision analog operation design: It can acquire the sensor signals accurately and quickly and can instantly obtain the system operating condition for control strategy operation.

- Remote communication technology: It can remotely collect the fuel cell system parameters for diagnosis.

- Automatically operating the monitoring system: It has system error prediction and smart debugging functions.

- Electromagnetic compatible design: It can avoid electromagnetic wave interference, thus increasing product reliability.

- Isolated Communications interfaces: CAN 2.0, RS485, RS232

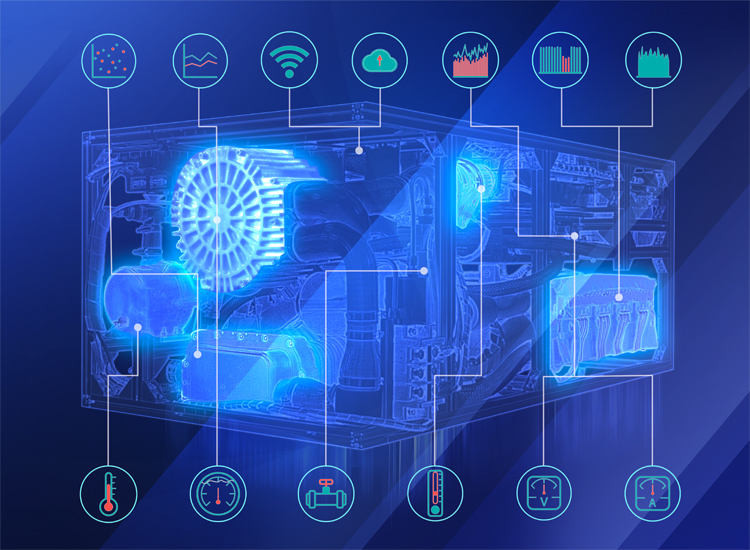

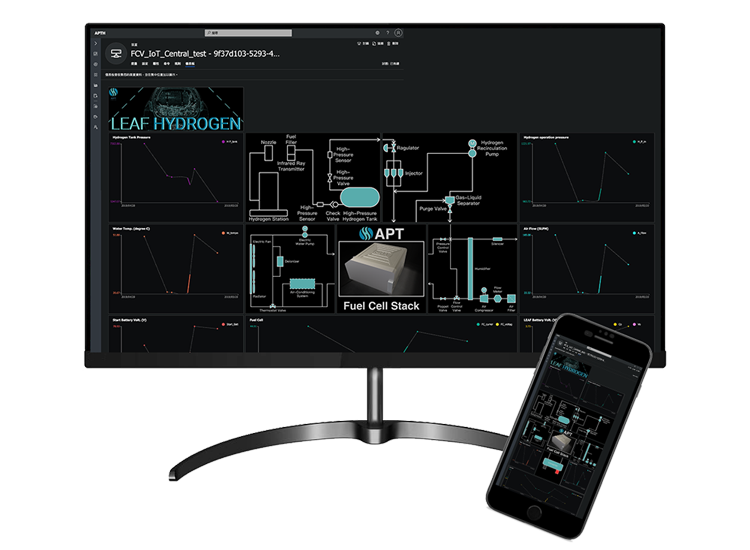

IoT Function

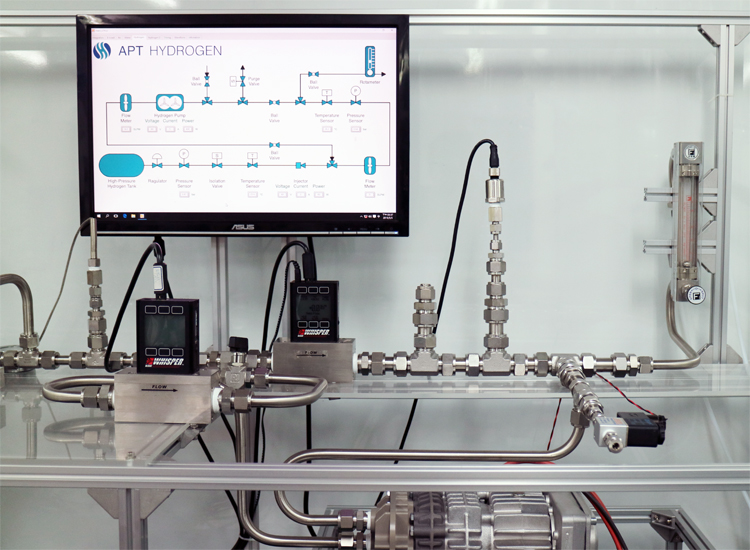

The APT fuel cell controller has built a basic IoT function that uses wireless transmission technology to transmit system operating data measured by sensors back to the cloud platform. The iconized human-machine interface allows users to remotely monitor the real-time data, and clearly realize the system operating status that thus performing intelligent data analysis and system health diagnostic analysis. In addition, it is also to monitor the use of hydrogen to optimize the energy efficiency to facilitate the decision of the hydrogen fueling infrastructure.